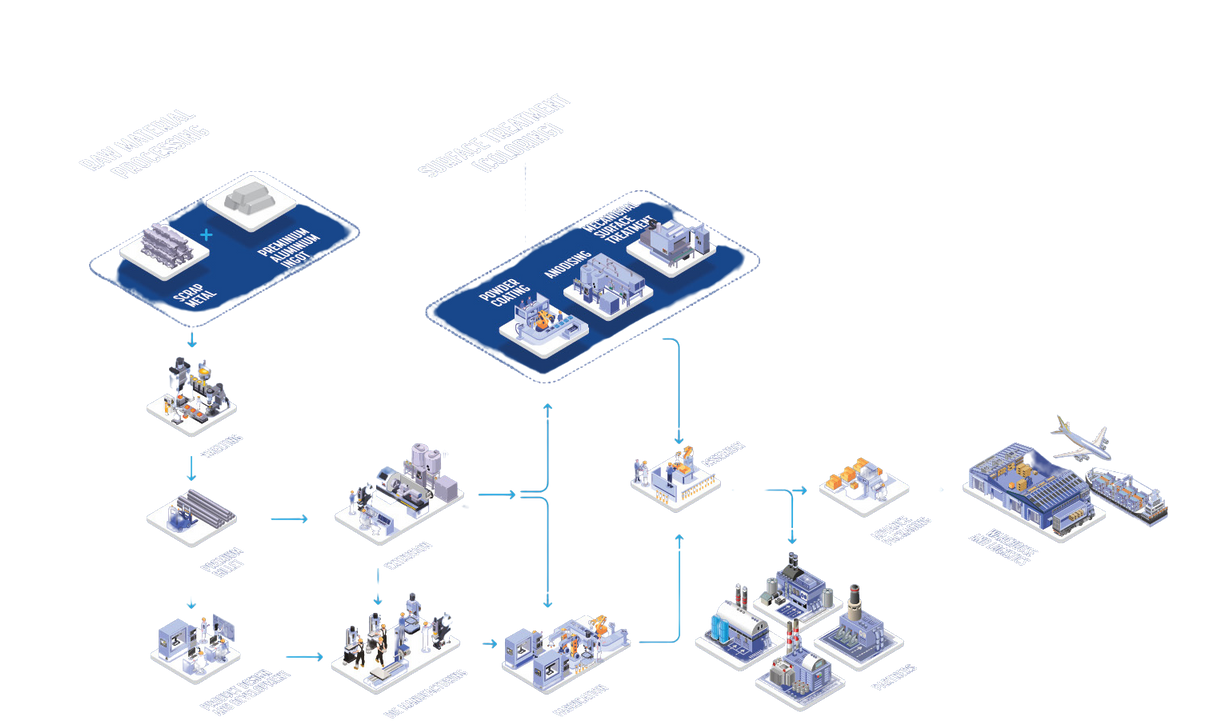

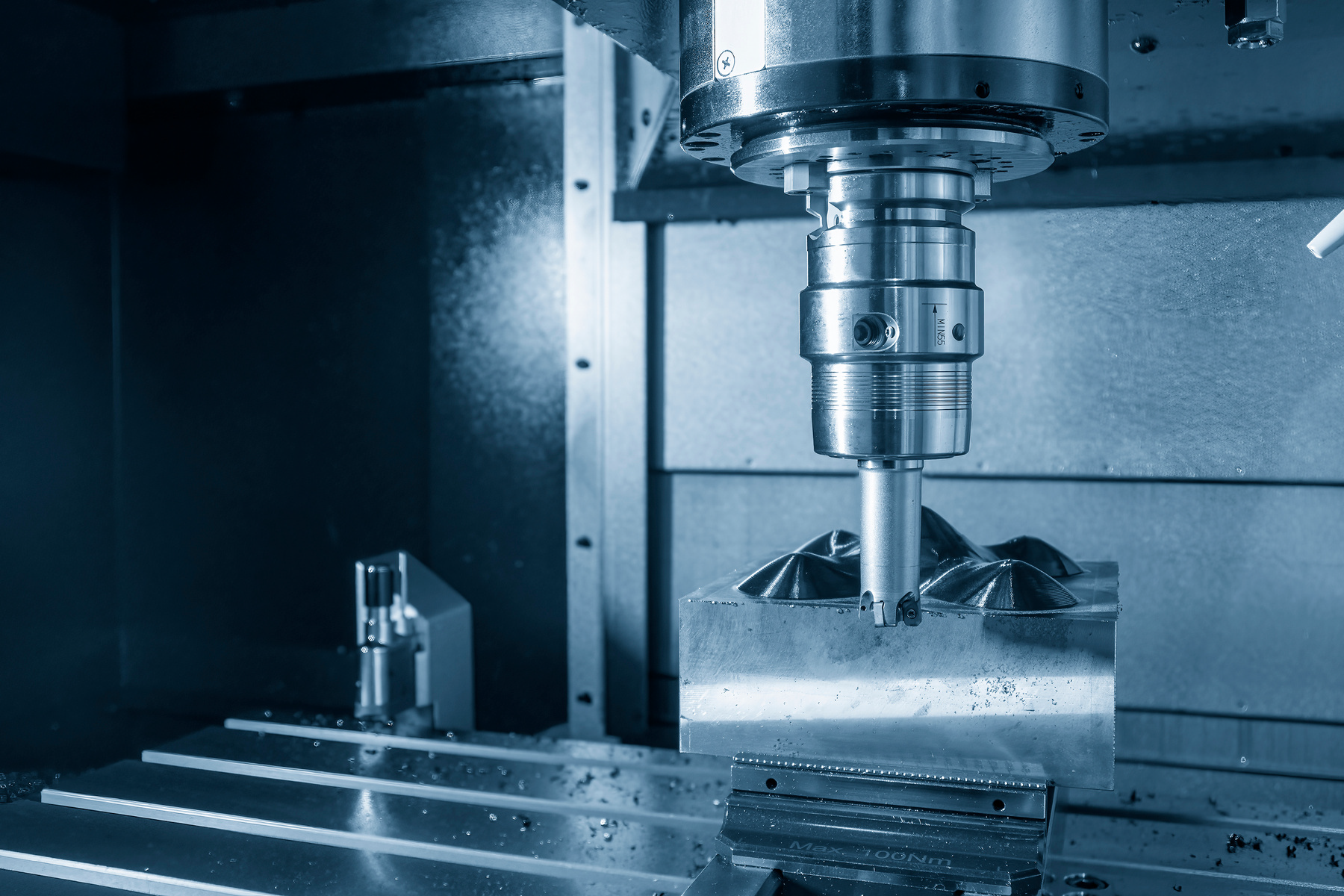

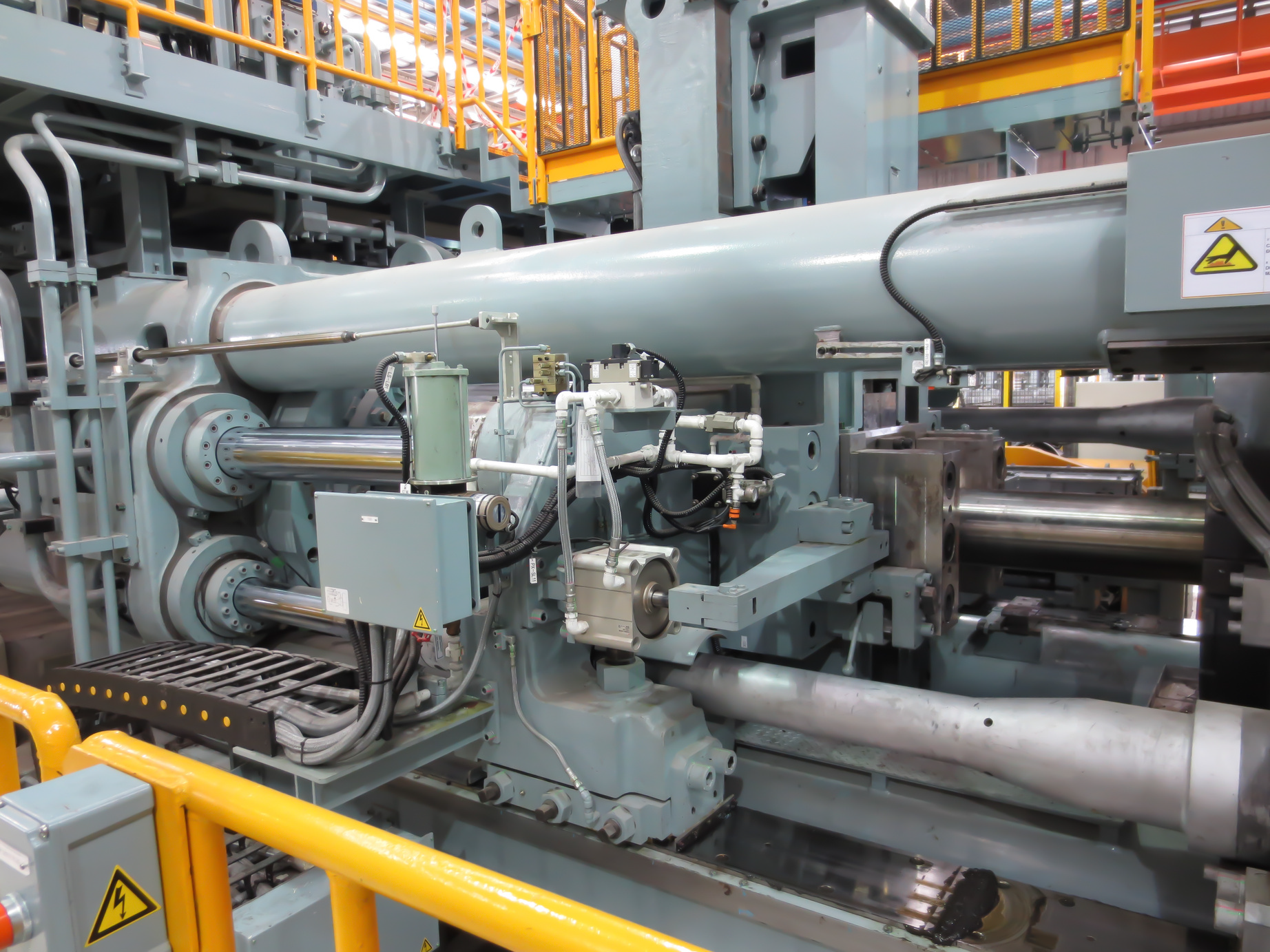

We specializes in producing high-performance aluminium products known for their strength, durability, and versatility. We cater to various sectors, including construction, manufacturing, and transportation. By prioritizing sustainable practices, we ensure that our products not only meet industry standard but also contribute positively to the environment. Our expert team provides innovative solutions that enhance efficiency and drive success for our partners.

At LLTP America, our mission is to empower our clients with high-quality products and unparalleled support.

Whether you’re a small business or a large enterprise, we are here to help you achieve your goals with our innovative aluminum and packaging solutions.